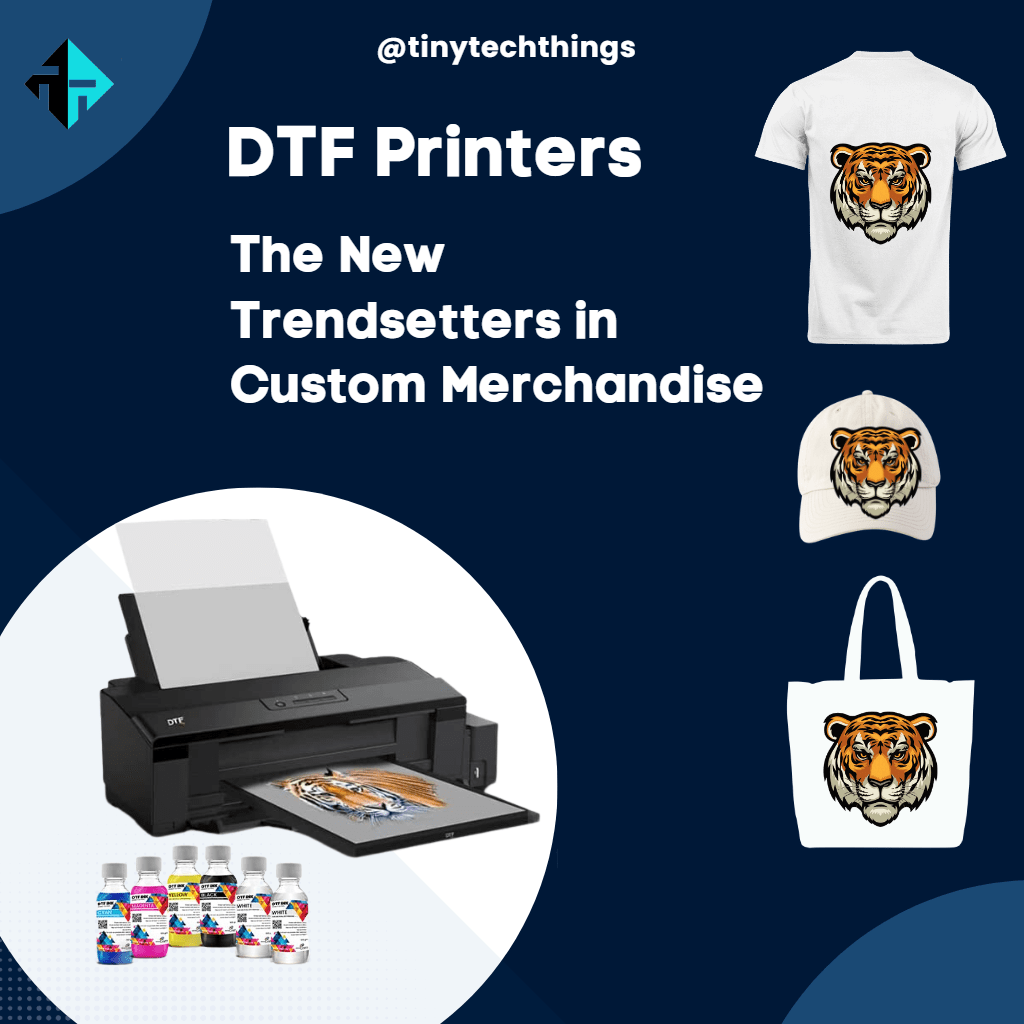

“Custom merchandise is taking the world by storm, and DTF Printers are at the forefront of this revolution.”

Table of Contents

– This attention-grabbing statement highlights the growing popularity of custom merchandise and introduces DTF Printers as the driving force behind this trend. It creates curiosity and sets the tone of this article.

What are DTF Printers?

DTF printers are cutting-edge digital printing machines specifically designed for printing on fabric surfaces. They use advanced technology to directly transfer ink onto the fabric, producing vibrant and long-lasting prints. This innovative printing method offers immense creative possibilities and has recently gained significant popularity.

How DTF Printers Work

DTF printers employ a two-step process to create high-quality prints on fabric. First, a special ink is printed onto a transfer film, which acts as a carrier. Then, the transfer film is placed on the fabric and subjected to heat and pressure, causing the ink to transfer and adhere to the fabric fibers. This results in vivid, durable prints that can withstand repeated washing and maintain their original color and clarity.

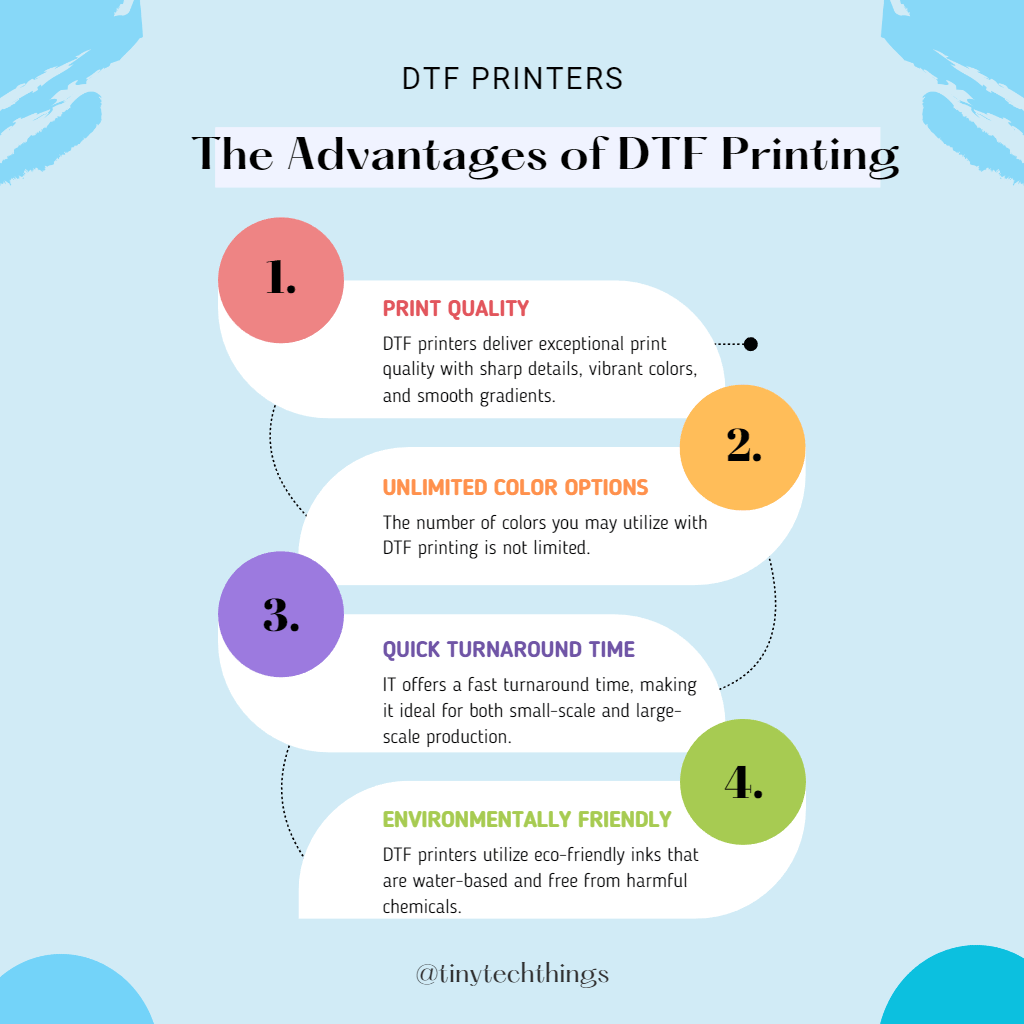

The Advantages of DTF Printing

DTF printing offers numerous advantages over traditional printing methods. Here are some key benefits:

Exceptional Print Quality

DTF printers deliver exceptional print quality with sharp details, vibrant colors, and smooth gradients. The ink penetrates the fabric fibers, resulting in prints that are soft to the touch and maintain their original appearance for a long time.

Unlimited Color Options

The number of colors you may utilize with DTF printing is not limited. The printers can reproduce complex designs with an extensive color range, allowing you to create eye-catching and intricate prints.

Quick Turnaround Time

DTF printing offers a fast turnaround time, making it ideal for both small-scale and large-scale production. The process is efficient and allows for high-speed printing, ensuring you can promptly fulfill orders.

Cost-Effective Solution

DTF printing offers a fast turnaround time, making it ideal for both small-scale and large-scale production. The process is efficient and allows for high-speed printing, ensuring you can promptly fulfill orders.

Environmentally Friendly

DTF printers utilize eco-friendly inks that are water-based and free from harmful chemicals. The printing process produces minimal waste and consumes less energy compared to other printing techniques, making it a sustainable choice for businesses and individuals alike.

The Versatility of DTF Printers

DTF printers offer incredible versatility, enabling you to print on a wide range of fabric materials. Whether you want to create custom t-shirts, hoodies, tote bags, or even home décor items, DTF printers can handle various fabric types, including cotton, polyester, blends, and more. This versatility allows for endless creativity and customization options.

DTF Printing vs. Traditional Printing Methods

DTF printing differs from traditional printing methods, such as screen printing and heat transfer, in several aspects. Unlike screen printing, which necessitates the creation of separate screens for each color, DTF printers have the ability to print intricate designs with an unlimited range of colors in just one pass. Additionally, DTF printing offers better color vibrancy, durability, and a softer feel compared to heat transfer methods.

Factors to Consider When Choosing a DTF Printer

When selecting a DTF printer for your business or personal use, several factors should be considered:

Print Size and Resolution

Evaluate the maximum print size and resolution capabilities of the DTF printer. This will determine the level of detail and size of designs you can print.

Ink Compatibility

Check the ink compatibility of the DTF printer. Some printers may support specific types of ink, so ensure it aligns with your requirements.

User-Friendliness

Consider the ease of use and user-friendly features of the DTF printer. Look for printers with intuitive interfaces and convenient controls to streamline your printing process.

Maintenance and Support

Research the maintenance requirements of the DTF printer and the availability of technical support. Regular maintenance ensures optimal performance and longevity of the printer.

Tips for Successful DTF Printing

Consider the following suggestions for getting the finest DTF printing results:

Prepare High-Quality Designs

Ensure your designs are high-resolution and suitable for the intended fabric. Vector graphics or high-quality raster images work best for crisp and clear prints.

Test and Calibrate

Before printing a large batch, perform test prints and calibrate the printer settings to achieve accurate colors and optimal print quality.

Proper Fabric Preparation

Prepare the fabric by pre-treating it with an appropriate solution to enhance ink adhesion and prevent color bleeding. Follow the manufacturer’s recommendations for the best results.

Optimize Heat and Pressure

Experiment with different heat and pressure settings to find the optimal combination for your fabric type. Proper heat and pressure ensure proper ink transfer and adherence.

DTF Printers and Sustainability

Sustainability is a growing concern in the printing industry. DTF printers contribute to a more sustainable approach to printing by using eco-friendly inks, minimizing waste, and reducing energy consumption. By choosing DTF printing, you can align your business with eco-conscious practices and cater to environmentally-conscious customers.

The Rise of Custom Merchandise

Custom merchandise is on the rise as consumers increasingly seek unique ways to express their individuality. Influenced by social media and a desire for emotional connections, personalized products offer brand differentiation and exclusivity. Technological advancements, like DTF printers, have made customization more accessible, catering to shifting consumer behavior that prioritizes experiences and self-expression. This trend is expected to continue growing, presenting opportunities for businesses and individuals alike.

DTF Printers in the Fashion Industry

The fashion industry thrives on uniqueness and personalization. DTF printers have revolutionized the way designers and fashion entrepreneurs create custom apparel. With DTF printing, fashion designers can unleash their creativity, produce limited edition collections, and offer personalized garments to their customers, all while maintaining excellent print quality and durability.

DTF Printers for Promotional Products

Promotional products play a crucial role in brand marketing and customer engagement. DTF printers provide an ideal solution for creating custom promotional items such as t-shirts, caps, bags, and more. The ability to print intricate designs, vibrant colors, and even individualized messages makes DTF printing a powerful tool for businesses to promote their brand effectively.

DTF Printers in the Art and Craft Community

Artists and crafters are embracing DTF printing as a means of expressing their creativity. The versatility of DTF printers allows artists to print their designs on fabric, opening up a world of possibilities for textile art, home decor, and personalized crafts. DTF printers empower artists to transform their artwork into functional and visually stunning pieces.

DTF Printers and Small Businesses

Small businesses can leverage the power of DTF printers to differentiate themselves in the market. By offering custom merchandise, small businesses can cater to niche markets and provide unique products that stand out from mass-produced alternatives. DTF printers allow small businesses to compete on a level playing field and establish their brand identity through customized offerings.

The Future of DTF Printing

As technology continues to advance, we can expect further innovations in DTF printing. Future developments may include faster printing speeds, expanded color gamuts, improved ink formulations, and enhanced compatibility with a broader range of fabrics. The future of DTF printing holds endless possibilities for customization and personalization in various industries.

Conclusion

DTF printers can print on various fabric types, including cotton, polyester, blends, and more. However, it’s important to check the specific printer’s capabilities and recommendations for optimal results.

FAQs

What is the difference between DTF printing and screen printing?

DTF printing allows for unlimited colors in a single pass, while screen printing requires separate screens for each color. DTF printing also offers better color vibrancy, durability, and a softer feel compared to screen printing.

Can DTF printers print on all types of fabric?

DTF printers can print on various fabric types, including cotton, polyester, blends, and more. However, it’s important to check the specific printer’s capabilities and recommendations for optimal results.

Are DTF printers suitable for small-scale production?

Yes, DTF printers are suitable for both small-scale and large-scale production. They offer a quick turnaround time and efficient printing process, making them ideal for fulfilling orders promptly.

Are DTF inks environmentally friendly?

Yes, DTF inks are eco-friendly as they are water-based and free from harmful chemicals. DTF printing produces minimal waste and consumes less energy compared to other printing techniques, making it a sustainable choice.

Can you print DTF on a regular printer?

No, DTF printing requires specialized DTF printers that are designed specifically for printing on fabric surfaces. Regular printers are not capable of performing DTF printing.

Is DTF or DTG better?

The choice between DTF (Direct-to-Fabric) and DTG (Direct-to-Garment) printing depends on various factors. DTF printing offers exceptional print quality, unlimited color options, and the ability to print on a wide range of fabric materials. DTG printing, on the other hand, excels in producing high-resolution prints on garments. Both methods have their strengths and are suitable for different applications.

Which is better, DTF or sublimation?

DTF printing and sublimation printing are both popular methods for printing on fabric, but they have some differences. DTF printing allows for vibrant colors, intricate designs, and printing on various fabric types. Sublimation printing involves transferring ink to a special coating on the fabric, resulting in long-lasting, vibrant prints. The choice between DTF and sublimation depends on factors such as the desired outcome, fabric type, and personal preference. Each method has its advantages and is suitable for different applications.

2 thoughts on “DTF Printers: The New Trendsetters in Custom Merchandise”

Pingback: Printers: The Unsung Heroes of Office Productivity - Tinytech Things

Pingback: Top 5 Best Printer For Home Use - Tinytech Things

Comments are closed.